High Performance Double Glazing

Our Double Glazed Unit (DGU) range is produced using cutting-edge technology from Forel, a leading manufacturer of machinery designed specifically for the flat glass industry. Our DGU Line is equipped with a Spacer Bender, Desiccant Machine, Primary Seal Applicator, and the DGU Line itself, ensuring precision and efficiency in every unit. Additionally, we use a state-of-the-art Arrising Machine, providing flawless edge work for superior glass performance.

How we Set the Standard

Leading the Way with Unrivaled Double Glazed Units

Making the shift from standard single glazing has never been more important, as the way in which we build changes, it is crucial to ensure your home or project uses the finest solutions in order to maximise performance and efficiency.

Or DGU’s are carefully crafted with two or more glass panes separated by a desiccated air space. DGU’s offers far better thermal efficiency, sound insulation and comfort to that of standard single glazing. Making our ranges an essential, yet smart choice for renovations and new builds.

Our DGU range offers a variety of solutions each unique in structure and performance, ensuring your home or project receives the very best tailored solution. See below how we are insuring the very best double-glazed products on offer.

The Perfect Process

Our meticulous approach begins with primary corner sealing, ensuring a secure and durable bond that stands up to the elements. Our commitment to excellence extends to the finer details, as we meticulously clean and inspect every secondary seal, guaranteeing a flawless finish.

The Human Touch

All our DGU ranges are meticulously crafted by skilled professionals who bring years of experience to every step of the production process. From precision cutting to meticulous assembly, our team ensures that each unit meets the highest standards of quality and durability.

The FGS Service

With a track record of over 99.9% accuracy, our production process ensures that our units are right the first time, eliminating the hassle of replacements or adjustments. Pair this with over 98.5% of our deliveries arriving on time with full tracking capabilities and SMS updates, you can rest assured you’re receiving the best DGU experience the industry has to offer.

The Production Process

A DGU (Double Glazed Unit) consists of the following;

-2 Pieces of Glass

-Spacer Bar filled with desiccant

-Sealed with either Polysulphide or Silicon

Watch below to see how we meticulously craft our DGU Range.

What does each part of the line do?

From the video above, you can see there are several steps to go through when making a DGU. The steps are;

Glass Manufacture

Manufacture Glass to suit the particular application and performance you are looking for.

Spacer Bar Manufacture

The spacer bar creates a gap between the 2 pieces of glass to help with insulation. the spacer bar is typically made of aluminium but can be made of other materials that do not conduct heat/cold as much as aluminium. However, these different materials will often be more expensive.

Spacer Bar Desiccant

Once the spacer is bent the hollow centre is filled with small desiccant beads. This desiccant is used to take away any moisture that may be present inside the sealed DGU.

Primary Seal

The primary seal is heated butyl that is applied to the outside of the spacer bar and is used to attach the spacer bar to both pieces of glass. This seal will stop moisture from entering the unit and will stop gasses such as Argon or Krypton from leaving the space in the DGU.

Secondary Seal

The secondary seal is the area between the spacer bar and the edges of the glass. In most cases, this is filled with polysulphide but on exposed edges, especially with UV exposure, silicon is typically used. This secondary seal gives added protection to the primary seal and gives a nice aesthetic look to the unit.

The Science Behind DGU

Understanding the performance of double-glazed units can be complex, but we’ve simplified it to help you grasp the essentials. While the science behind insulation and solar control involves intricate glass technologies, we’ve broken it down to explain how our products work to keep your home comfortable year-round, reducing heat transfer in summer and retaining warmth in winter. For further details be sure to ask your fabricator, they should be able to assist you with all the expert advice needed to assist you when selecting which DGU works best for your project.

Understanding Insulation

(U-Value)

How it Works

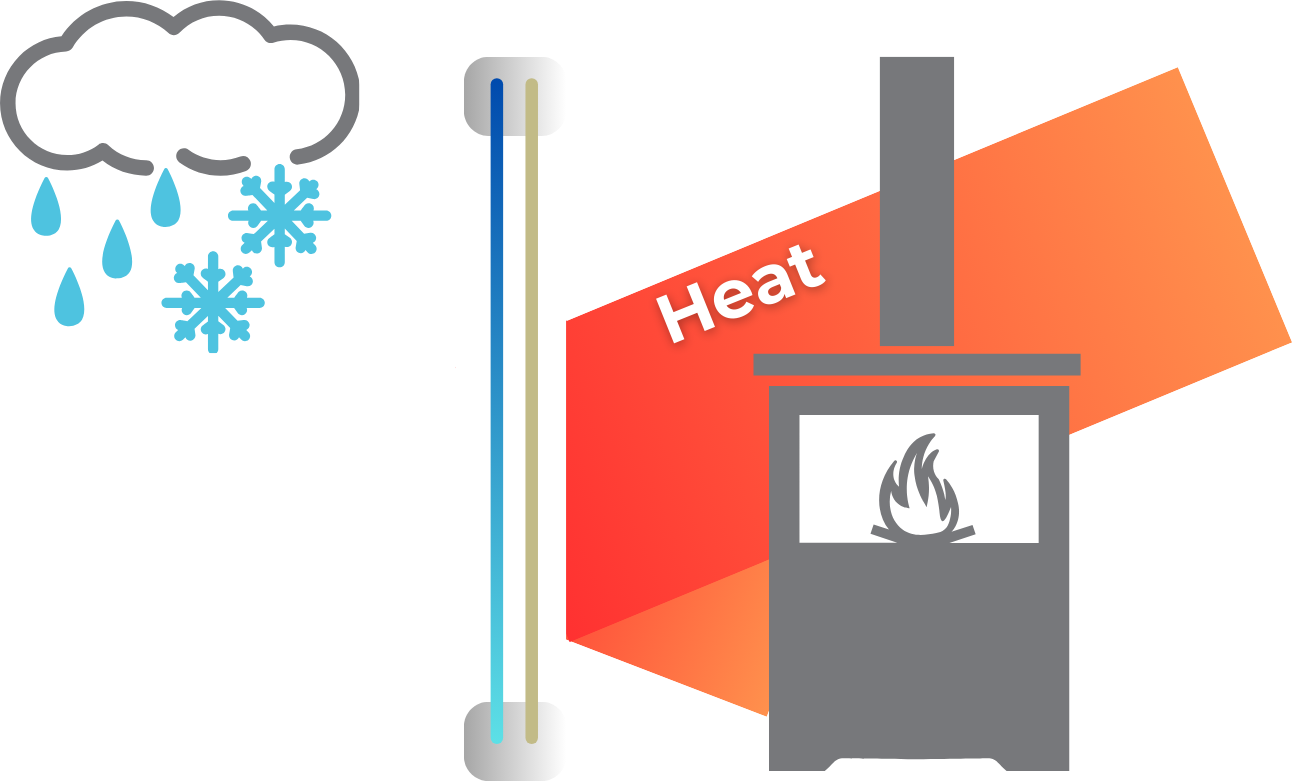

The U-Value measures how well a window stops heat from escaping your home. The lower the U-Value, the better the insulation. In Victoria’s cooler months, this means your home stays warmer for longer, reducing the need for extra heating. Across the board, all our DGU ranges offer impressive insulation properties, but it’s in solar control where we truly start to see a noticeable difference in performance. The diagram helps to show in a simple format how our units work to maintain a comfortable indoor temperature and save on energy costs.

Understanding Solar Control

(SHGC)

How it Works

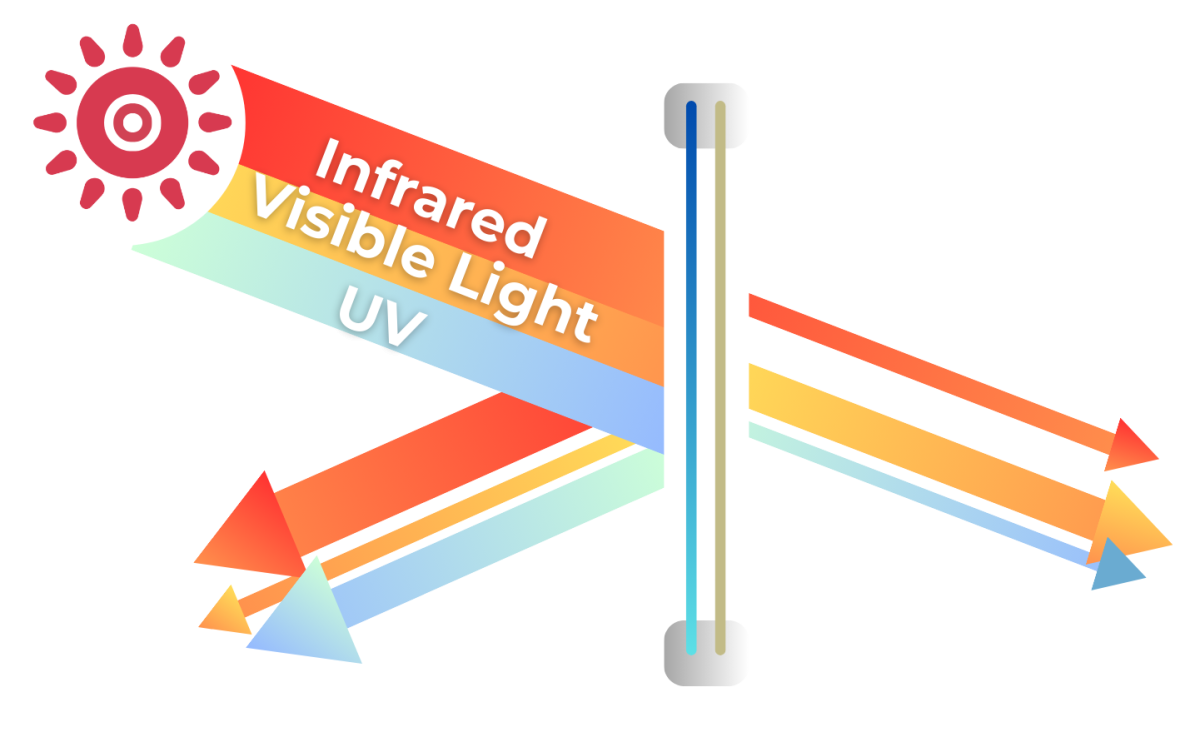

The Solar Heat Gain Coefficient (SHGC) measures how much heat from the sun passes through a window. A lower SHGC means better solar control, which is crucial during Victoria’s hot summer months. With improved SHGC, our double-glazed units help keep your home cooler by reducing the amount of heat entering, lessening the need for air conditioning and lowering cooling costs. While all our DGU ranges offer strong insulation, it’s in solar control where the performance difference truly shines. The diagram provides a simple breakdown of how our units work to maintain comfort and energy efficiency.

Double Glazed Units

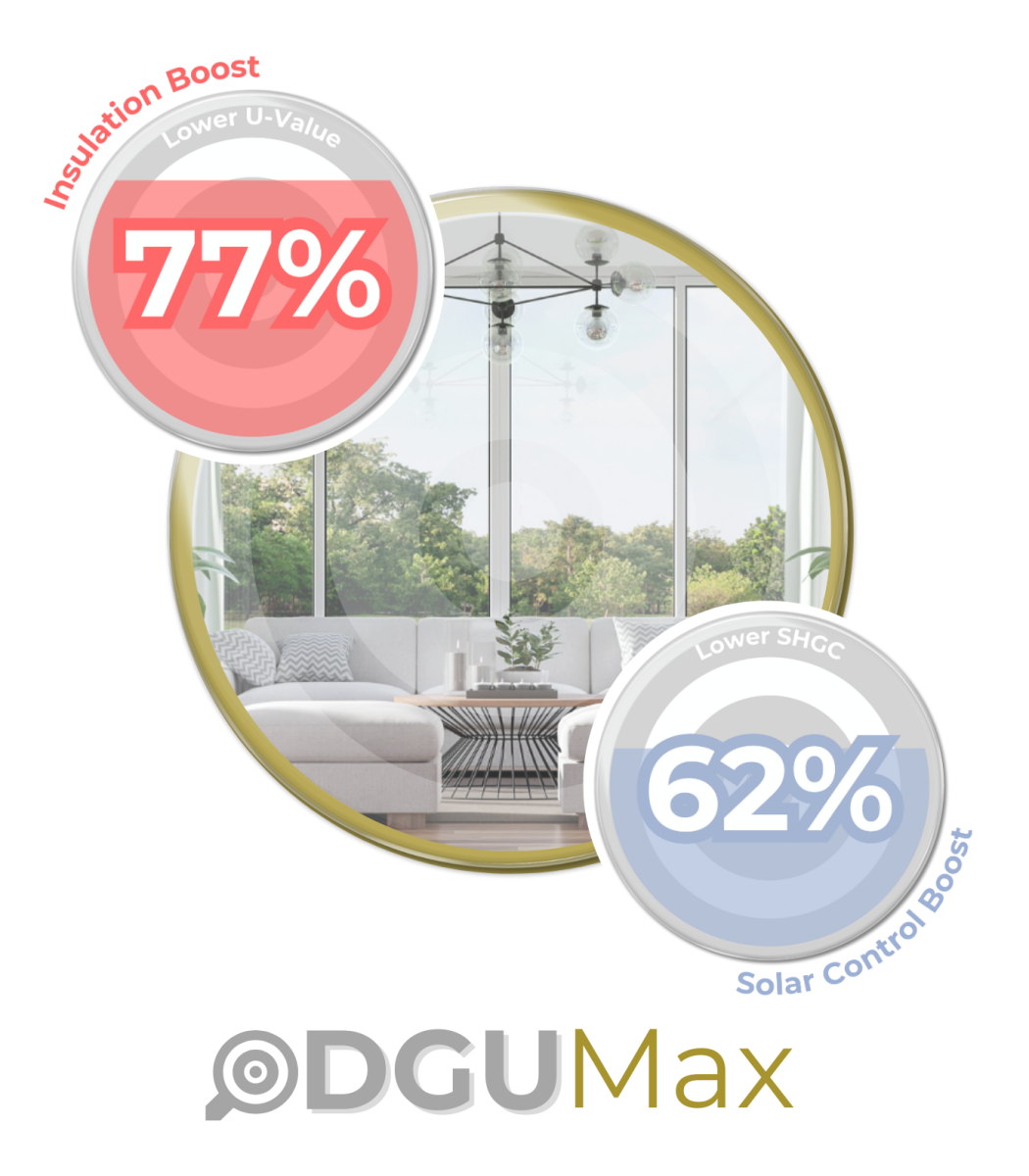

Our double-glazed units offer the perfect solution when ensuring your home remains energy efficient, use the comparison tool to see the difference in performance between our range.

Be sure to check detailed performance data to see specifically how our units perform.

*The performance data presented here is benchmarked against standard 4mm float glass. For DGU Essential, the configuration is 6mm Clear | 12mm Argon Spacer | 6mm Clear. DGU Pro utilises 6mm Clear | 12mm Argon | 6mm EnergyTech. DGU Premium features 6mm Clear | 12mm Argon | 6mm LightTech, and DGU Max is composed of 6mm LightTech LI Max | 12mm Argon | 6mm Clear. For more detailed performance data, please refer to the individual product pages by selecting ‘Click here to explore the range.’