TreadSafe

TreadSafe Glass offers a unique solution for flooring and stair treads, allowing natural light to flood your interiors while providing essential safety features. Imagine transforming your home’s spaces with light and style, creating an open, connected environment that feels both modern and inviting.

TreadSafe Glass is perfect for use as floor panels or stair treads, fitting seamlessly into various architectural designs. Safety is key, and we offer fully engineered solutions tailored to your specific needs. Our Technical Lamination Manager is available to help ensure the correct glass thickness and construction, giving you peace of mind and optimal performance in every application.

Exploring The Benefits

Strength and Durability

VueSafe interlayers are engineered to be five times stronger and up to 100 times stiffer than conventional laminating materials.

Versatile Applications

From floors and stairs to balcony rails and minimally supported glass canopies, VueSafe is a versatile solution for a wide range of applications.

Non-Slip

Add Text

DGU Application

?

Easy Processing

Can be toughened, laminated, curved or used in DGU Pro.

Weather Resistant

Can be used externally without fear of delamination, making it ideal for applications where exposure to the elements is inevitable.

Safety

TreadSafe has a laminated layer that contributes towards making the range a Grade A safety glass as standard.

Range of Tones

Colour options are available within the TreadSafe range.

Non Slip Flooring

FGS have 2 types of different non slip flooring. These can be used in conjunction with Custom Toughened Laminated Glass and can either be directly laminated to the other pieces of glass or can be used as a sacrificial piece of glass on laminated flooring. As a sacrificial layer, this piece of glass can be easily replaced if it breaks or gets damaged. However, if you have any moisture between the 2 pieces of glass you may encounter an oil can effect, where you may be able to see a rainbow effect between the sheets.

The 2 types of glass that are available are

- Etched Glass

- The pattern is etched into the glass

- Abrasive Paste Glass

- The pattern is applied to the glass and is baked through the toughening cycle

Different types of non slip glass carry a non slip rating, called a ‘P’ rating. This ranges from a P1 glass which has very little amount of non slip ability, upto P4 with is extremely non slip and can be used in many applications, including wet areas. All of FGS Glass Non Slips have been independently tested and have a specific ‘P’ Rating. FGS Glass’s Stairtread/flooring system is called TreadSafe

Non Slip ‘P’ Rating

All of the FGS Glass Non Slip surfaces have been tested through a NATA accredited test Laboratory. We know that our different types of glass range from P1 upto P4. Below is a brief summary of our Non Slip Glass Types

- Frosted Embossed Etched Glass – P3/P4

- Clear Embossed Etched Glass – P1

- Abrasive Paste Glass – P4

The classifications for each rating are shown below. It gives a clear understanding of where each type of non slip surface is recommended to be used. Each non slip glass has an SRV score, which then relates to the ‘P’ classification. The useage can range from wet swimming pool surrounds P4 down to Dry entry and exit access areas P1. Please talk to our Technical Lamination Manager on 03 8562 0880 for advice on Non Slip Flooring

‘P’ Rating Descriptions

Use the drop downs below to learn more...

P4 Classification (SRV 45 – 54)

- External ramps including sloping driveways, footpaths etc., under 1 in 14, external sales areas (eg markets), external carpark areas, external colonnades, walkways, pedestrian crossings, balconies, verandas, carports, driveways, courtyards, and roof

- Serving areas behind bars in public hotels and clubs, cold stores and

- Swimming pool surrounds and communal shower rooms

P3 Classification (SRV 35 – 44)

- Undercover carparks

- Entries and access areas including hotels offices, public buildings, schools, kindergartens, common areas of public buildings, internal lift lobbies – WET4 areas

- Toilet facilities in offices, hotels and shopping

- Fast food outlets, buffet food servery areas, food courts and fast food dining areas in shopping centres.

- Shop and supermarket fresh fruit and vegetable areas

- Shop entry areas with external entrances

- Other separate shops inside shopping centres – WET6

- Communal changing rooms

- Undercover concourse areas of sports stadiums

- Bathrooms and en-suites in hospital and aged care facilities

P2 Classification (SRV 25 – 34)

- Entries and access areas including hotels offices, public buildings, schools, kindergartens, common areas of public buildings, internal lift lobbies – TRANSITIONAL5 areas

- Hotel apartment bathrooms, en-suites and toilets

- Hotel apartment kitchens and laundries

- Wards and corridors in hospital and aged care facilities

P1 Classification (SRV 12 – 24)

- Entries and access areas including hotels offices, public buildings, schools, kindergartens, common areas of public buildings, internal lift lobbies – DRY6 areas

- Supermarket aisles (except fresh food areas)

- Other separate shops inside shopping centres – DRY5

Standards Australia handbook HB 198:20142 does not list suitable locations for surfaces with a P0 rating and therefore it could be concluded that the finish is not suitable for use in any location that may become wet at any time. According to the Notes to Table 3B of HB198 “…some smooth and polished floor surfaces, which do not achieve Classification P1, may be considered to provide a safe walking environment for normal pedestrians walking at a moderate pace, provided the surfaces are kept clean and dry; however, should these surfaces become contaminated by either wet or dry materials, or be used by pedestrians in any other manner, then they become unsafe.”

Thermal & Optical Performance Data

| key2 | Tilt Tilt-angle (°) Angle of the glass relative to the horizon

|

Ug.w Ug (W/m².K) Heat-transfer coefficient (center-of-glass)

.w NFRC 100-2010 Winter Condition

|

Ug.s Ug (W/m².K) Heat-transfer coefficient (center-of-glass)

.s NFRC 100-2010 Summer Condition

|

SHGC SHGC (Range: 0 – 1) Solar heat gain coefficient

|

VLT VLT (Range: 0 – 1) Visible light transmittance

|

VLRf VLRf (Range: 0 – 1) Front Visible light reflectance

|

VLRb VLRb (Range: 0 – 1) Back Visible light reflectance

|

Tdw Tdw-ISO (Range: 0 – 1) Damage weighted transmittance

|

Tuv Tuv (Range: 0 – 1) UV transmittance

|

Sel. Selectivity (VLT/SHGC) Ratio of visible light transmittance over solar heat gain coefficient

Example:

|

rgbhex | Nom. Nominal thicknesses (mm) List of nominal thicknesses of the IGU components separated by the '+' symbol Example: 17.52:

6+12+6:

|

Total. Total thickness (mm) Total thickness of the glazing system; sum of component thicknesses |

Visual | fontcolour | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Loading ITables v2.1.4 from the internet...

(need help?) |

Applications

TreadSafe is versatile and can be used in a wide range of interior and exterior applications:

Exterior:

Interior:

Specifications

How to Specify

Versatile Applications: TreadSafe Glass can be used as floor panels or stair treads, offering a versatile solution for various architectural designs. Safety is paramount when using glass in these applications, and our Technical Lamination Manager is available to assist with calculations for glass thickness and construction. We provide fully engineered solutions tailored to your specific requirements, ensuring peace of mind and optimal performance.

Safety Considerations: Laminated glass is recommended for TreadSafe applications to prevent catastrophic failure in case of glass breakage. Our Technical Lamination Manager can guide you through the design process, considering factors such as glass size, loading, and support systems to ensure structural integrity and safety.

Surface Finish and Grip: To prevent slipping, care must be taken with the finished surface of TreadSafe Glass. Options such as etched or abrasive paste surfaces can improve grip and reduce the risk of slipping, especially in wet locations. Explore our Non-Slip Flooring options to learn more about enhancing safety with TreadSafe Glass.

Non-Slip Glass Options: TreadSafe Glass offers two non-slip finishes:

- TreadSafe Embossed Glass

- TreadSafe Acrylic Resin Glass

Considerations

Things to Consider

Sizes

Our Embossed Glass is available in full sheets, however we have a theoretical max size of 2050mm x 3600mm

If you are looking for larger sizes, please contact us first. In some instances we may be able to do larger sizes.

Take a look at the 5 types of Embossed Glass below and call our Technical Laminating Manager on 03 8562 0880 for more information

Non Slip Glass Types – Embossed Etched Glass

Embossed Etched Glass is available in full sheet sizes 3660mm x 2440mm. It comes in 2 types of finish

- Crystal Frost Etch Low Iron (Right)

- Frosted Etch has the same finish as Satin Frost, which means it is not clear. It gives a diffused look

- Frosted Etch has a high ‘P’ Rating. It is typically rating between P3 and P4, the two highest ratings

- Crystal Clear Etch Low Iron (Left)

- Clear Etch looks just like clear glass, which means you can see through it.

- Clear Etch has a much lower ‘P’ Rating. It typically has a ‘P’ rating between P1 and P2, with most patterns being P1. This means the glass has some some non slip properties but is not recommended in a number of applications

Look at the header photo above to see the difference between Frost and Clear Etched Glass

Non Slip Glass Types – Abrasive Paste Glass

Abrasive Paste Glass is available up to 1600mm x 810mm or 2000mm x 610mm, this is considerably smaller than the Etched Non Slip glass. Abrasive Paste Glass is only available on clear glass. On larger jobs, this could be extended to Ultra Clear, Satin Frost, Crystal Frost and Euro Grey.

- Abrasive Paste Glass

- Abrasive Paste Glass has the same finish as Clear, which means you can see through it.

- Abrasive Paste Glass has the highest ‘P’ Rating. It is typically rating at P4, which is the highest rating

- The major downside is that we are limited by the size of the glass sheets available. This size restraint will mean Abrasive Paste Glass cannot be used on larger jobs.

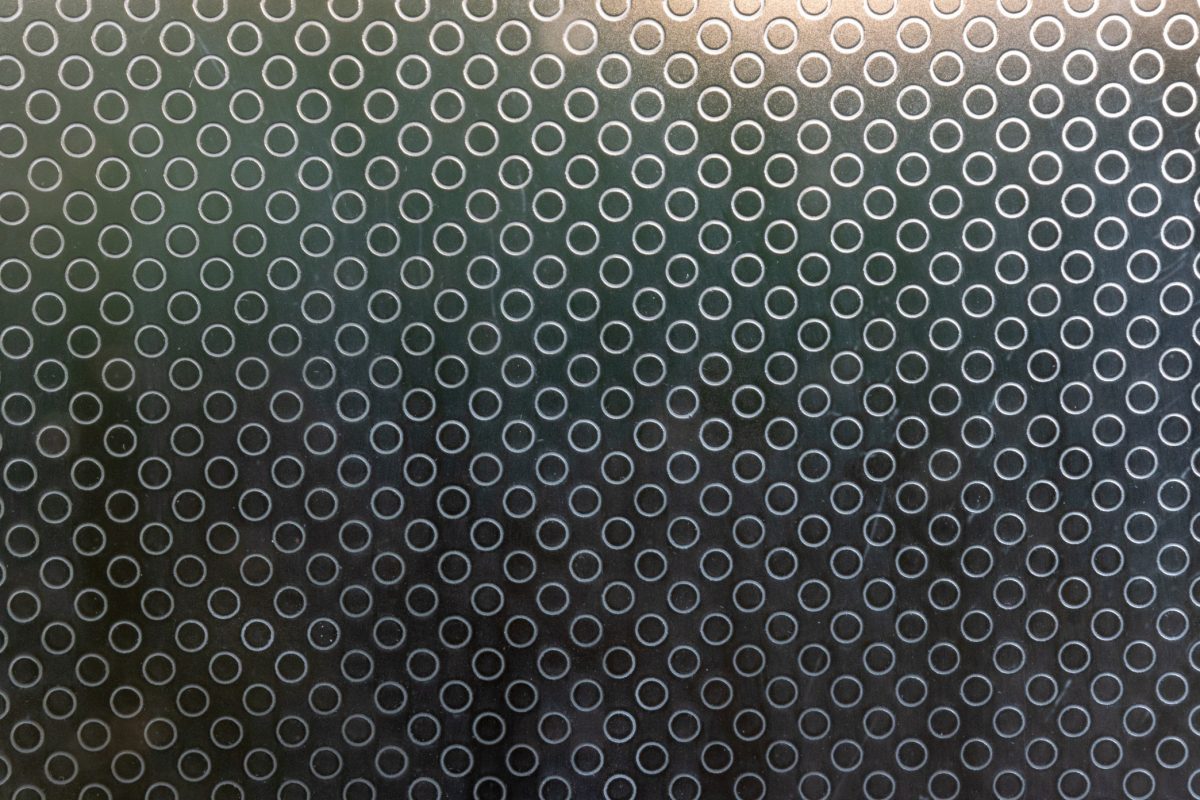

Look at the header photo above to see our circle pattern and the FGS Logo pattern.

TreadSafe – Embossed Glass Non Slip Flooring

TreadSafe comes in both Embossed (Etched) and Abrasive Paste Non Slip Glass. Both are very different in terms of sizing and finish.

Our Embossed Glass comes in 5 finishes

- Embossed FGS X Crystal Clear (P1)

- Embossed FGS X Crystal Frost (P3)

- Embossed Circle Crystal Clear (P1)

- Embossed Circle Crystal Frost (P3)

- Embossed Ring Crystal Frost (P4)

Our Embossed Glass has been chemically etched, to remove part of the glass surface, leaving a raised pattern. This glass can then either be clear or can have a frosted etch finish. All of our Embossed Glass is Low Iron.

The Frosted finish has a better ‘P’ (Non Slip) rating, allowing it to be used in numerous applications. The Clear finish is more aesthetically pleasing, allowing you to see through the flooring but its ‘P’ rating is not as good and is limited to certain applications. Both have their place and you can choose the finish to suit your individual circumstances.

EMB FGS X Crystal Clear / Crystal Frost

This pattern is truly unique to FGS as it is based on the FGS Spider fitting that is used in the logo. This pattern is aesthetically pleasing and has great symmetry.

‘P’ Rating

- EMB FGS X Crystal Clear – P1

- EMB FGS X Crystal Frost – P3

EMB Circle Crystal Clear / Crystal Frost

This pattern is well know and used in lots of applications. It consists of a solid xmm circle, which is raised up. It comes in both a Clear and Frosted finish

‘P’ Rating

- EMB Circle Crystal Clear – P1

- EMB Circle Crystal Frost – P3

EMB Ring Crystal Frost

This pattern consists of a raised xmm circle. Only the edges of the circle are raised. The centre of the ring has also been etched. This pattern gives a great ‘P’ rating. However this pattern only comes in a frosted finish.

‘P’ Rating

- EMB Ring Crystal Frost – P4